FAQ –

Frequently asked questions.

How do I create a heat with more drivers than I have lanes. (Round-robin)

How can the best qualified driver be the first to choose lane.

When track power goes off, I sometimes get communication problems or

“unexpected reset”.

My remote control is not working.

LapMaster gets a different COM-port each

time I reconnect it to my computer.

Does LapMaster have a log of all laps

raced on the track.

How do I connect the LapMaster system.

How do I connect the LapMaster system to a

SRT power relay board.

|

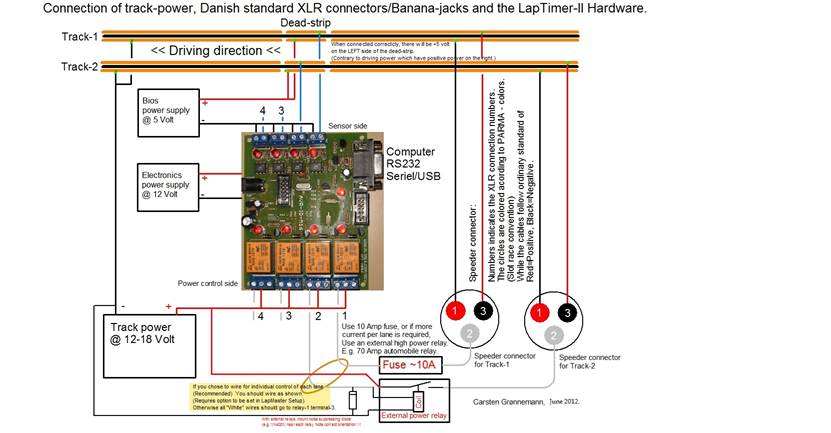

Question: How do I connect the

LapMaster system. Answer: You

might also have a look at this diagram: If

you are confused by the diagram, here is a more practical verbal guide on how

to connect a LapMaster system. Domestic Power: Deadstrip: These has been labeled Lane

1-4 and 5-8. Track power: If

you already have a SRT power relay connection board, see this How

do I connect the LapMaster system to a SRT power

relay board. It is

absolutely mandatory that your relay coils are equipped with what is known as

backlash-diodes. See

also: When track power goes off, I sometimes get communication

problems or “unexpected reset” Computer:

If

your Computer dosn't have

a serial port, use the supplied USB-to-Serial converter cable. When you

attach the cable the first time, the Computer If

you need to lengthen the distance from the computer to the LapMaster box, extend the serial cable. You should not

extend the USB cable. Software: After

installation, you must associate the LapMaster program

with the LapMaster hardware. To

do that, start the LapMaster program. Accept the

"Demo" mode the first time you start LapMaster. (LapMaster must be connected and powered). Click

"OK" to save the connection. LapMaster

will close. Start

LapMaster the second time. Now click on

"Setup"->"Track Setup", and customize LapMaster to suit your track. (Number

of lanes, lane colors, length, name etc.) Click on "OK" to

complete. LapMaster will close. You

can now restart LapMaster for the 3'rd time, and

you are now ready to race. LiveTiming: |

|

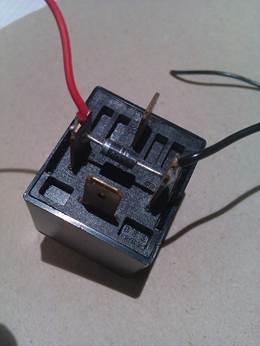

Question: How do I

connect the LapMaster system to a SRT power relay board. Answer: If

you have an existing SRT relay board hooked up, connection of LapMaster could not be any easier. The SRT

relay board looks like this: This is a

closeup of the relevant connections: The LapMaster box comes with relay connections wired to a screw

terminal connector block: That’s it,

for the power connection. See How do I

connect the LapMaster system. For the remaining

aspects. |